Is Pressure Treated Wood Waterproof?

Everyone knows pressure treated wood to be resistant to insect attacks such as termites, which degrades wood, but many people don’t know if pressure treated wood is waterproof. Although treated wood contains chemicals passed into the wood under high pressure, which makes it utterly resistant to biological attack by insects, even though pressure treated contains chemical preservatives, it is not resistant to water and moisture.

Hence, pressure treated wood has to be waterproofed by sealing agents that will form a protective coat over the wood’s surface. You can use various sealants such as varnish, polyurethane, lacquer, wood oils, etc., to waterproof your wood and make it durable enough to serve its purpose.

All at a Glance

Is pressure treated wood waterproof?

Pressure treated wood has been an excellent choice for interior and exterior household furniture as it is one of the most durable wood because it is pressure treated. Pressure treated wood contains preservative chemicals that resist attacks by insects, such as termites that eat away the wood, making the wood rot. The fact that pressure treated wood is resistant to insects doesn’t make them resistant to water.

The wood soaks and loses moisture, which eventually weakens the wood. To keep your wood waterproof, you have to apply a coat of waterproofing agent on the wood to make it water-resistant, and every once in a few years, you can retouch the wood with a coat of waterproofing treatments to keep it durable. With proper care and maintenance, pressure-treated wood can last for at least 40 years, but you have to keep it from prolonged exposure to sunlight and UV rays to improve its durability.

How to waterproof pressure treated wood

You can waterproof your wood by using various seals that will protect your wood and build an excellent resistance to water. You can use polyurethane, lacquer, varnish, wood oils, stain, and seal combination to waterproof your wood, which eventually improves your wood’s durability. Each sealing agent varies in its method and mode of application, curing time, and durability, but all these waterproof agents effectively make the wood resistant to water.

Polyurethane Sealants

Polyurethane sealants contain different ingredients that allow you the luxury of selecting your favorite finish other than the acrylic and polyurethane resins. You get to choose any type, from a high-gloss shine to a soft sheen. One of the advantages of the latest polyurethane finish produced is that they don’t yellow quickly over time, which is an excellent quality that makes them great on light-toned woods.

However, oil-based polyurethane comes with so much durability that it makes the wood last longer; however, you’ll have to employ mineral spirits to clean the brushes after your application. Water-based polyurethane is easier to clean as it doesn’t require mineral spirits; all you need is water and soap.

Varnish Sealants

Varnish sealant comes from resin, solvent, and drying oil, which gives a hard-shell finish that resists scratches without giving a yellow coloration. To waterproof your wooden structures, especially those used outdoors, it is advisable to use marine varnish to seal the wood. The varnish contains UV absorbers that reduce the sun’s effects on the wood, and instead, the UV absorbers take in the sunlight’s effects instead of the wood.

Spar varnish is most suitable for interior wooden furniture such as tea table. The varnish resists sticky cup rings. You’ll need either mineral spirits or turpentine to clean up your wood.

Lacquer is a mixture of either tree resin or synthetic resin dissolved in alcohol. It is one of the best sealants, majorly for wood furniture. However, this wood preservative can develop a yellowish pigmentation with time, giving coloration to lighter woods.

Even at that, it brings out a rich, luxurious, and extraordinary finish that can resist scratches if used on a deep-toned wood. Lacquer is available in different types, and you can use lacquer thinner to thin it if you want to make it lighter.

Methods on how to waterproof pressure treated wood

We will outline three methods that will show you the step-by-step process of waterproofing your furniture easily without stress, waterproofing using sealants, wood oils and stain, seal combination. Take note always to follow the manufacturer’s instructions as regards the type of product you’re using. This will help you take note of the relevant details regarding the type of product you’re to use.

The Use of Sealants (varnish, polyurethane, or lacquer)

The use of sealants is one of the best ways to use to give your pressure-treated wood resistance against water. Applying polyurethane, varnish, or lacquer methods gives excellent waterproofing results, which protects the wood from being vulnerable to moisture. You can choose to apply any of these waterproofing agents using a brush, spraying a polyurethane finish on an adequately prepared wood surface. After applying, allow the ample finish time to dry completely before you sand, and then after sanding, apply another layer.

Water-based polyurethane takes about 6 hours to dry completely, while oil-based takes up to 24 hours to dry. The curing time of the two polyurethane types extends as long as 30 days, although water-based polyurethane dries faster than oil-based, which makes it one of the reasons why some people prefer it over oil-based.

Polyurethane formulas dry extremely fast, and a little as few may take as little as 15 minutes to dry. Polyurethane contains volatile organic compounds, most especially the oil-based polyurethane products. That is why you have to ensure that you are working in a properly ventilated environment during the application.

Read Also: Is Pressure Treated Wood Safe for Vegetable Gardens?

Using wood oil(linseed oil) to create a warm, hand-rubbed oil finish

For this first step, we will be using tung oil and linseed oil gotten from the tung tree and seeds of the flax plant, respectively. These two oils are mostly used in creating a warm, hand-rubbed finish. Wood oil is renowned for centuries for their great functions as they protect the dark-grained woods such as walnut and mahogany, the oil preserves and keeps it waterproof.

You can mix the two oils with few other essential ingredients to make the perfect solution to waterproof your pressure-treated wood as well as the unpainted wood pieces. You can either buy pre-blended linseed and tung oil or buy them separately and mix them to get your wood oil.

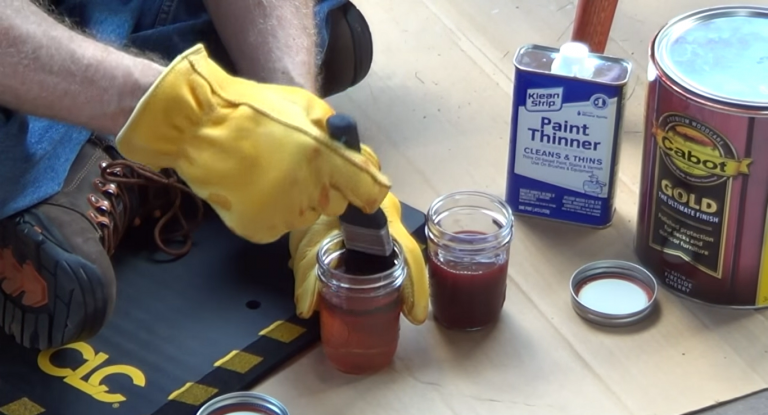

A suitable hand-rubbed oil mixture consists of one part of either two oils, one-part polyurethane, and one part mineral spirits. To start with, mix and stir all the ingredients thoroughly, then use a natural bristle paintbrush to apply it on the wood pieces evenly. Then allow the oil to get absorbed into the surface, take note to skip any spot, and once you notice a dry area, apply another layer on it.

After the wood is evenly applied, wipe off the residual oil using a dry towel or rag to remove all the excess oil from the wood’s surface. After wiping all the excesses, allow the wood to dry completely. The drying time depends on the amount of oil used, but it is advisable to let it dry overnight.

After the wood is dried, use sandpaper for sanding the wood gently. You can repeat the whole process to get a perfect finish. This simple process will protect your wood from moisture.

The use of stain and sealant combination

To protect your wood from being vulnerable to moisture, you can apply the method of using a stain and sealant combination. A stain and sealant formula doesn’t only seal your wood surface but also stains it simultaneously, making it a dual purpose waterproofing agent. These formulas save you the time and money of having to buy and apply the two separately.

Almost all stain sealant products containing color pigments that consist of extra binders. These particular binders can either be oil or water-based. As a result of these binders, you might have your binders varying from transparent,semi-transparent, and even opaque. The result of your finish depends on the concentration of the formula’s pigment you’re using.

When dealing with exterior furniture, you should reapply after every year to ensure that you keep your wood surface sealed and ensure that it is always in the best condition. Majorly, the stain-sealants formulas do not build upon the wood. Instead, they soak into the wood, allowing excess sealant applied to evaporate except for alkyd-based products.

Unlike water and oil-based sealants, alkyd-based adhesives usually leave a light surface coating on the wood’s surface, which makes them perfect to use for interior wooden structures that don’t necessarily require future reapplications.

If used on the exterior wooden furniture, you will notice that the alkyd-based stain-sealers will most likely start to peel, especially when the wood is not well-prepared to apply the formula, which means oil and water-based sealants are most suitable for waterproofing outdoor wood pieces.

Tools and materials needed

- Mineral spirits

- Polyurethane

- Linseed and tung oil

- Natural bristle paintbrush

- Rags and towel

- Fine-grit sandpaper

- Liquid detergent

- Water

- Safety goggles.

- Sprayer

Conclusion- Is Pressure Treated Wood Waterproof?

So far, it’s been discussed, and pressure-treated wood is resistant to rot. It prevents biological attacks by termites and insects that infest wood, degrading and weakening it, making the wood crack giving room to decay. Although the chemical preservatives present in pressure treated wood is resistant to rot, they’re not waterproof. They readily absorb moisture, which makes the wood swell and eventually give room to decay.

The treated lumber has to be waterproofed for it last longer. It can be waterproofed using three methods; the use of wood oil to create a protective hand-rubbed finish, the use of sealants to seal the surface of the wood, and a stain sealant combination that gives your surface protection against water.

Important Reads: